With all the writing I’ve been doing about yeast lately, I thought it would probably be a good idea to outline my general yeast propagation and storage procedures. There’s an enormous variation, both philosophically and technically, among homebrewers – from directly pitching a smack pack to acid washing and storage in -80°C freezers. My own techniques are based on two sometimes contradictory goals:

- Emulate professional brewers’ procedures whenever possible, in an endless pursuit of better beer.

- Minimize the expense of brewing, in terms of both time and money.

#1 precludes simply throwing in a smack pack and hoping for the best, and #2 precludes buying new yeast every time I brew. So I find myself a reluctant yeast rancher. There are many ways of storing yeast, and all of them have been tried by other home brewers at one time or another, so I’m not going to go into details here. Suffice it to say that the cheapest and easiest is to store yeast slurries in an ordinary refrigerator. If you’re going to be using the yeast within a few weeks, you can even harvest it directly from the fermenter and re-pitch into the next batch. I don’t really brew often enough for that to be practical, and I also worry about the strain of repeated high-gravity fermentations causing mutations, so I propagate solely in un-hopped 1.030 starter wort. In effect, this means I’m always pitching first-generation yeast, although I’ll probably start over every few dozen batches anyway, just for peace of mind.

Except for when I’m starting a new strain from a smack pack, the cycle begins and ends with a 100 mL glass jar that’s stored in my beer fridge. It’s pretty important to get a reasonable estimate of the number of cells in the starting population; any errors here will be compounded throughout the rest of the process. For the sake of simplicity, I’m going to assume the slurry is a cylinder 3 mm in height and 6 cm in diameter. It’s almost exactly a month old, so the viability should be about 75%. Assuming a density of 4.5 billion/mL, there should therefore be about: π(3 cm)2(0.3 cm)(4.5 billion/mL)(0.75) = 29 billion viable cells. That’s enough that I’m going to step up only twice. For an older slurry (fewer than about 10 billion cells), I would do a three-stage propagation.

Except for when I’m starting a new strain from a smack pack, the cycle begins and ends with a 100 mL glass jar that’s stored in my beer fridge. It’s pretty important to get a reasonable estimate of the number of cells in the starting population; any errors here will be compounded throughout the rest of the process. For the sake of simplicity, I’m going to assume the slurry is a cylinder 3 mm in height and 6 cm in diameter. It’s almost exactly a month old, so the viability should be about 75%. Assuming a density of 4.5 billion/mL, there should therefore be about: π(3 cm)2(0.3 cm)(4.5 billion/mL)(0.75) = 29 billion viable cells. That’s enough that I’m going to step up only twice. For an older slurry (fewer than about 10 billion cells), I would do a three-stage propagation.

Unless poor planning or a heavy brewing schedule have drained my supply, I do all my propagations using the tail runnings from a previous mash that I store in the freezer. This is the ultimate cost-cutting measure; as I continue to use a particular strain, the yeast cost per batch approaches zero. These particular tail runnings are from a doppelbock, so they’re darker than usual. Since I’m going to be decanting the starters, that isn’t a huge issue – and this is being pitched into a stout anyway. For a very light beer I would have to plan ahead, or bite the bullet and buy some DME. They’re also higher-gravity than usual, at about 7°P (1.028). Ordinarily the tail runnings would end up closer to 3-5°P (1.012-1.020) and need to be boiled down by about half.

Unless poor planning or a heavy brewing schedule have drained my supply, I do all my propagations using the tail runnings from a previous mash that I store in the freezer. This is the ultimate cost-cutting measure; as I continue to use a particular strain, the yeast cost per batch approaches zero. These particular tail runnings are from a doppelbock, so they’re darker than usual. Since I’m going to be decanting the starters, that isn’t a huge issue – and this is being pitched into a stout anyway. For a very light beer I would have to plan ahead, or bite the bullet and buy some DME. They’re also higher-gravity than usual, at about 7°P (1.028). Ordinarily the tail runnings would end up closer to 3-5°P (1.012-1.020) and need to be boiled down by about half.

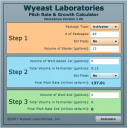

For the first stage I’m going to use 500 mL. (When building up from an older slurry I would start with 200 mL, then 500.) The chief drawback to using the MrMalty calculator for this kind of thing is that it won’t deal with starter volumes smaller than 1 L – presumably because that’s roughly the minimum size needed to get significant growth out of a smack pack. So for the first stage, I use the Wyeast calculator instead. As you can see, it predicts that my 500 mL starter will produce about 137 million cells/mL, or 68 billion total. So it’s basically back up to the cell count of a smack pack.

For the first stage I’m going to use 500 mL. (When building up from an older slurry I would start with 200 mL, then 500.) The chief drawback to using the MrMalty calculator for this kind of thing is that it won’t deal with starter volumes smaller than 1 L – presumably because that’s roughly the minimum size needed to get significant growth out of a smack pack. So for the first stage, I use the Wyeast calculator instead. As you can see, it predicts that my 500 mL starter will produce about 137 million cells/mL, or 68 billion total. So it’s basically back up to the cell count of a smack pack.

Now I can move back to the MrMalty calculator, manually setting the viability to 68%. For this particular beer, I therefore need roughly a 2.5 L starter. I’m using the “continuous aeration” setting, not because I am aerating continuously – only as much as foaming allows – but because that’s the setting that most closely matches my own slurry measurements, adjusted for 1.030 wort. My highly sophisticated aeration setup consists of an “Elite 800” model aquarium air pump, with two 0.45 μm syringe filters in series, and a disposable plastic air stone. I like the disposable stones because they produce very fine bubbles, and can be thrown away instead of trying to sanitize the microscopic pores. The stainless steel nut is there to keep the air stone from floating to the top of the starter.

Now I can move back to the MrMalty calculator, manually setting the viability to 68%. For this particular beer, I therefore need roughly a 2.5 L starter. I’m using the “continuous aeration” setting, not because I am aerating continuously – only as much as foaming allows – but because that’s the setting that most closely matches my own slurry measurements, adjusted for 1.030 wort. My highly sophisticated aeration setup consists of an “Elite 800” model aquarium air pump, with two 0.45 μm syringe filters in series, and a disposable plastic air stone. I like the disposable stones because they produce very fine bubbles, and can be thrown away instead of trying to sanitize the microscopic pores. The stainless steel nut is there to keep the air stone from floating to the top of the starter.

Be sure to allow enough time – 3-4 days per stage – to have the yeast ready by brew day. After each stage, I refrigerate the starter overnight, then decant as much liquid as possible, both to remove the alcohol and to maximize the surface:volume ratio. The whole idea here is to keep the yeast as healthy as possible, and avoid any potential long-term complications. Before cooling the final stage, though, I resuspend the yeast and pour off 100 mL of the starter into a jar. This keeps a protective layer of beer over the yeast for storage, and ensures you won’t select a substantial number of mutants that are either more or less flocculent than the population as a whole. The jar is then sealed, labeled with the strain, number of “generations”, and the date, and placed in the fridge for next time. Yeast stored this way can be revived and built back up to a pitchable population after well over a year.

Be sure to allow enough time – 3-4 days per stage – to have the yeast ready by brew day. After each stage, I refrigerate the starter overnight, then decant as much liquid as possible, both to remove the alcohol and to maximize the surface:volume ratio. The whole idea here is to keep the yeast as healthy as possible, and avoid any potential long-term complications. Before cooling the final stage, though, I resuspend the yeast and pour off 100 mL of the starter into a jar. This keeps a protective layer of beer over the yeast for storage, and ensures you won’t select a substantial number of mutants that are either more or less flocculent than the population as a whole. The jar is then sealed, labeled with the strain, number of “generations”, and the date, and placed in the fridge for next time. Yeast stored this way can be revived and built back up to a pitchable population after well over a year.

Because I know you’re curious, the yeasts I’m currently keeping on hand are:

- Wyeast 1028 London Ale (Worthington White Shield)

- Wyeast 1056 American Ale (Sierra Nevada)

- Wyeast 1084 Irish Ale (Guinness)

- Wyeast 1272 American Ale II (Anchor Liberty)

- Wyeast 2035 American Lager (August Schell)

- Wyeast 2206 Bavarian Lager (Weihenstephan 206)

- Wyeast 3787 Trappist High Gravity (Westmalle)

- Wyeast 3864 Canadian/Belgian Ale (Unibroue)

- Wyeast 3944 Belgian Witbier (Celis White)

With these nine strains I feel I can brew just about anything (at least anything I brew regularly), without having two that would be substantially similar.

Sean,

You mention that the size of the starting population is very important. I believe that this is not the case. The more you grow the more will the size of the final population depend on the amount of nutrient (I.e. The gravity and amount of propagation wort) used to grow the yeast. At least this seems to be my observation.

Kai

Very interesting, Kai. You’re saying that a given amount of fermentable sugar will result in the same final population, no matter what the starting population was? I would have assumed that wasn’t the case due to fermentation by the existing yeast consuming some of the sugars, but maybe the effect is relatively small. I haven’t done any final slurry volume measurements for multiple pitching rates; I may have to give that a try. Thanks!

[…] (39) Popular PostsYeast Pitching Rate ResultsAeration and Yeast StartersLOL @ MazurYeast Ranching and YouYeast Pitching Rate ExperimentRegulating Fermentation TemperaturesBuild a Better StirplateWater, […]

I wouldn’t say that the starting propulation does not matter at all but the more yeast you grow the less it will matter. If the wort you are using is able to provide nutrients for 90B cells and you start with 10B cells you get 100B cells. If you start with 2x the population (20B cells) you can expect to get 110B cells. In the end the difference was only 10%.

I see that all the time when I start from a very small polulation and grow it into a full pitch of yeast. Was matters for the final yeast amount is not so much that starting population but the amount of wort I end up using and how I propagate the yeast.

Cheers,

Kai

That does sound like it matches up with my observations. I was just thinking that logically, if you start with more cells, more fermentation would occur and consume some of the sugars that would otherwise be used for sterol synthesis. So in your example maybe 10B cells would result in 100B, but 20B cells would result in 109B – though I have no idea what the quantitative effect would actually be.

If you haven’t seen any significant impact, I’ll take your word for it. I’m not equipped to do cell counts and am just estimating from slurry volumes, so I doubt I could get the resolution necessary with any reasonably sized starter.

I’m also assuming that the yeast have access to all the resources they need. If you weren’t providing appropriate nutrients and/or oxygenating, I would definitely expect to see reproduction limited by whatever resource was scarcest – as I saw in the pure sucrose fermentations.

Sean

[…] store them? Is it just mixed in with wort like a starter? Basically, yes. Here's my procedure: Yeast Ranching and You […]

Awesome info. thanks so much for posting! :)

Hi. What sort of long-term shelf life have you have been getting storing your slurry in the refer? I have slants from Dec 2009 still full cream color in the bottom rear of my fridge; so I’m perplexed as to this method.

The longest I’ve gone is 17 months, which is right about where you are. I’m sure that (assuming there’s no contamination) they’d last years. It’s just a question of how much time you’re willing to put into stepping up the culture.

Sean

[…] have to take any more time than rehydrating the dry yeast or making a starter for the liquid. http://seanterrill.com/2010/03/23/yeast-ranching-and-you/ __________________ http://seanterrill.com/category/brewing/ […]

[…] should take a look at http://seanterrill.com/2010/03/23/yeast-ranching-and-you/. Sean has some great information about yeast ranching, calculating the number of cells in your […]

[…] out this website. http://seanterrill.com/2010/03/23/yeast-ranching-and-you/ Sean does a great job decribing the process and calculating the volume of your slurry. Here is […]

[…] career, I’ve bounced more or less randomly from one Belgian strain to another, in the process collecting most of the common strains, but without really settling on a “house” yeast. For the […]